Magnetic Particle Testing (MPT)

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current, which may be either alternating current (AC) or some form of direct current (DC) (rectified AC). The presence of a surface or subsurface discontinuity in the material allows the magnetic flux to leak, since air cannot support as much magnetic field per unit volume as metals. To identify a leak, ferrous particles, either dry or in a wet suspension, are applied to a part. These are attracted to an area of flux leakage and form what is known as an indication, which is evaluated to determine its nature, cause, and course of action, if any.

Types of electrical currents used

here are several types of electrical currents used in magnetic particle inspection. For a proper current to be selected one needs to consider the part geometry, material, the type of discontinuity one is seeking, and how far the magnetic field needs to penetrate into the part. Alternating current (AC) is commonly used to detect surface discontinuities. Using AC to detect subsurface discontinuities is limited due to what is known as the skin effect, where the current runs along the surface of the part. Because the current alternates in polarity at 50 to 60 cycles per second it does not penetrate much past the surface of the test object. This means the magnetic domains will only be aligned equal to the distance AC current penetration into the part. The frequency of the alternating current determines how deep the penetration. Full wave DC[clarification needed – discussion] (FWDC) is used to detect subsurface discontinuities where AC can not penetrate deep enough to magnetize the part at the depth needed. The amount of magnetic penetration depends on the amount of current through the part.[1] DC is also limited on very large cross-sectional parts in terms of how effectively it will magnetize the part. Half wave DC (HWDC, pulsating DC) works similar to full wave DC, but allows for detection of surface breaking indications and has more magnetic penetration into the part than FWDC. HWDC is advantageous for inspection process as it actually helps move the magnetic particles during the bathing of the test object. The aid in particle mobility is caused by the half-wave pulsating current waveform. In a typical mag pulse of 0.5 seconds there are 15 pulses of current using HWDC. This gives the particle more of an opportunity to come in contact with areas of magnetic flux leakage. An AC electromagnet is the preferred method for find surface breaking indication. The use of an electromagnet to find subsurface indications is difficult. An AC electromagnet is a better means to detect a surface indication than HWDC, DC, or permanent magnet, while some form of DC is better for subsurface defects.

Equipment

A wet horizontal MPI machine is the most commonly used mass-production inspection machine. The machine has a head and tail stock where the part is placed to magnetize it. In between the head and tail stock is typically an induction coil, which is used to change the orientation of the magnetic field by 90° from the head stock. Most of the equipment is built for a specific application.

Mobile power packs are custom-built magnetizing power supplies used in wire wrapping applications.

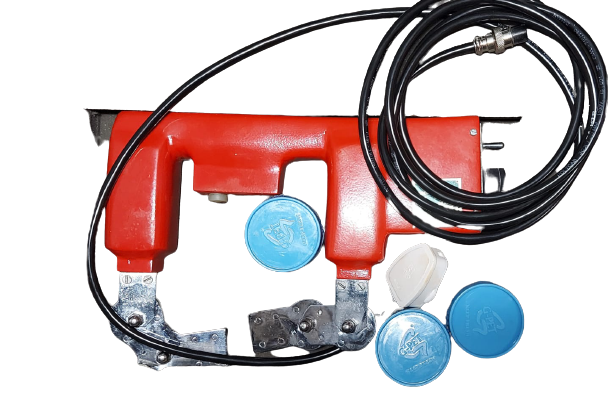

Magnetic yoke is a hand-held device that induces a magnetic field between two poles. Common applications are for outdoor use, remote locations, and weld inspection. The draw back of magnetic yokes is that they only induce a magnetic field between the poles, so large-scale inspections using the device can be time-consuming. For proper inspection the yoke needs to be rotated 90 degrees for every inspection area to detect horizontal and vertical discontinuities. Subsurface detection using a yoke is limited. These systems used dry magnetic powders, wet powders, or aerosols.